6300 Series Deep Groove Ball Bearings are designed for high-load capacity applications, offering reliable performance, reduced friction, and excellent operational stability. These bearings are built to endure both radial and axial loads, making them ideal for demanding environments. Available in various configurations, they cater to diverse industrial and commercial needs.

Features

- High Load Capacity: Designed to handle heavy radial and moderate axial loads efficiently.

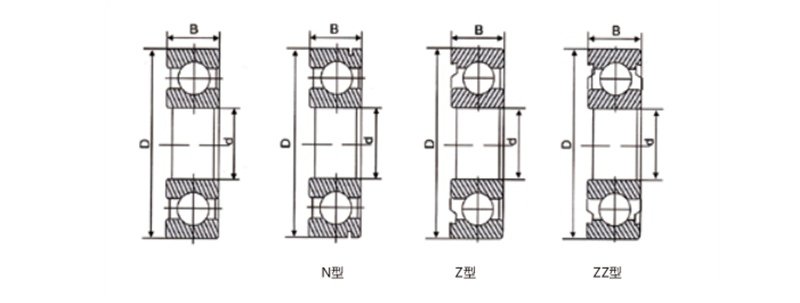

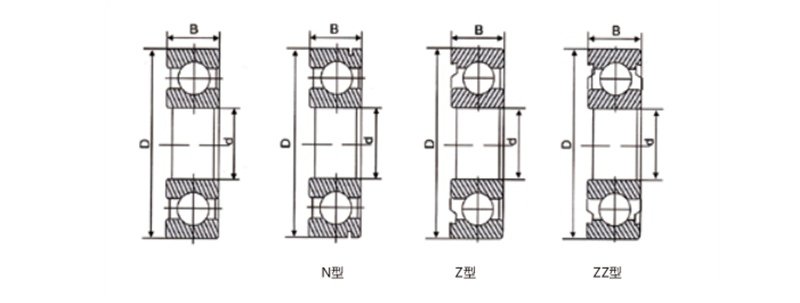

- Versatile Design: Available in open, sealed (2RS), and shielded (Z) variants for various operational environments.

- Durable Construction: Made with high-quality steel or stainless steel for extended service life.

- Smooth Operation: Precision manufacturing ensures reduced noise and vibration during operation.

- Corrosion Resistance: Stainless steel models offer superior resistance in harsh or moist environments.

- Pre-Lubricated: Comes pre-lubricated with high-quality grease for enhanced performance and minimal maintenance.

用途

- Agricultural machinery

- Industrial conveyors and machinery

- Automotive components (e.g., wheel hubs, transmissions)

- Power tools and pumps

- HVAC systems and compressors

- Heavy-duty motors and generators

| Bearing Designation |

Dimension(mm) |

Basic load

ratings (kN) |

Speed

ratings(rpm) |

Weight |

| Open |

RS |

ZZ |

d |

D |

B |

rs

min |

Cr |

Cor |

Grease |

Oil |

(Kg) |

| 6200 |

6200

RS |

6200

ZZ |

10 |

30 |

9 |

0.6 |

5.1 |

2.39 |

25000 |

30000 |

0.032 |

| 6201 |

6201

RS |

6201

ZZ |

12 |

32 |

10 |

0.6 |

6.1 |

2.75 |

22000 |

26000 |

0.037 |

| 6202 |

6202

RS |

6202

ZZ |

15 |

35 |

11 |

0.6 |

7.75 |

3.6 |

19000 |

23000 |

0.045 |

| 6203 |

6203

RS |

6203

ZZ |

17 |

40 |

12 |

0.6 |

9.6 |

4.6 |

18000 |

21000 |

0.066 |

| 6204 |

6204

RS |

6204

ZZ |

20 |

47 |

14 |

1 |

12.8 |

6.65 |

16000 |

18000 |

0.106 |

| 6205 |

6205

RS |

6205

ZZ |

25 |

52 |

15 |

1 |

14 |

7.85 |

13000 |

15000 |

0.128 |

| 6206 |

6206

RS |

6206

ZZ |

30 |

62 |

16 |

1 |

19.5 |

11.3 |

11000 |

13000 |

0.199 |

| 6207 |

6207

RS |

6207

ZZ |

35 |

72 |

17 |

1.1 |

25.7 |

15.3 |

9800 |

11000 |

0.288 |

| 6208 |

6208

RS |

6208

ZZ |

40 |

80 |

18 |

1.1 |

29.1 |

17.8 |

8700 |

10000 |

0.366 |

| 6209 |

6209

RS |

6209

ZZ |

45 |

85 |

19 |

1.1 |

32.5 |

20.4 |

7800 |

9200 |

0.398 |

| 6210 |

6210

RS |

6210

ZZ |

50 |

90 |

20 |

1.1 |

35 |

23.2 |

7100 |

8300 |

0.454 |

| 6211 |

6211

RS |

6211

ZZ |

55 |

100 |

21 |

1.5 |

43.5 |

29.2 |

6400 |

7600 |

0.601 |

| 6212 |

6212

RS |

6212

ZZ |

60 |

110 |

22 |

1.5 |

52.5 |

36 |

6000 |

7000 |

0.783 |

| 6213 |

6213

RS |

6213

ZZ |

65 |

120 |

23 |

1.5 |

57.5 |

40 |

5500 |

6500 |

0.99 |

| 6214 |

6214

RS |

6214

ZZ |

70 |

125 |

24 |

1.5 |

62 |

44 |

5100 |

6000 |

1.07 |

| 6215 |

6215

RS |

6215

ZZ |

75 |

130 |

25 |

1.5 |

66 |

49.5 |

4800 |

5600 |

1.18 |

| 6216 |

6216

RS |

6216

ZZ |

80 |

140 |

26 |

2 |

72.5 |

53 |

4500 |

5300 |

1.4 |

| 6217 |

6217

RS |

6217

ZZ |

85 |

150 |

28 |

2 |

83.5 |

64 |

4200 |

5000 |

1.79 |

| 6218 |

6218

RS |

6218

ZZ |

90 |

160 |

30 |

2 |

96 |

71.5 |

4000 |

4700 |

2.15 |

| 6219 |

6219

RS |

6219

ZZ |

95 |

170 |

32 |

2.1 |

109 |

82 |

3700 |

4400 |

2.62 |

1. What types of bearings do you offer?

We provide a wide range of bearings, including ball bearings, roller bearings, deep groove ball bearings, angular contact bearings, cylindrical roller bearings, self-aligning bearings, thrust bearings, needle bearings, and more. We also specialize in ceramic, hybrid, and custom-designed bearings.

2. Do you offer customized bearing solutions?

Yes, we provide OEM and custom bearing production services tailored to your specific needs. Share your requirements with us, and our expert team will help you design and manufacture the perfect bearing solution.

3. What materials are used in your bearings?

Our bearings are manufactured using high-quality materials such as Gcr15, ステンレス鋼 (304, 316, 440C), silicon nitride (Si3N4), zirconia (ZrO₂), PEEK, PTFE, and other advanced materials to ensure durability, precision, and reliability in various applications.

4. Can you provide samples before placing a bulk order?

Yes, we offer sample bearings for testing and evaluation. Please contact us with your sample request, and we’ll be happy to assist you.

5. What industries do you serve?

We cater to a diverse range of industries, including automotive, aerospace, agriculture, machinery, food processing, medical equipment, industrial automation, and renewable energy.

6. Do you export your products?

Yes, we export bearings worldwide, including to Europe, North America, Asia, and other regions. Our products comply with international quality standards and have been well-received by customers globally.

7. What is your minimum order quantity (MOQ)?

Our MOQ varies depending on the product type and customization requirements. For standard products, we offer flexible MOQ options. Contact us for details specific to your needs.

8. What is your production lead time?

Lead times depend on the type of bearing and order quantity. Standard bearings are typically ready for shipment within 2-4 weeks, while customized orders may take longer. We strive to deliver orders promptly to meet your deadlines.

9. How do you ensure product quality?

Our bearings are manufactured under strict quality control measures, including ISO certifications, precision testing, and rigorous inspections. Each product is tested to ensure compliance with international standards.

10. What payment methods do you accept?

We accept multiple payment methods, including wire transfer (T/T), PayPal, and credit cards. Contact our sales team for further assistance regarding payment options.

11. Do you provide technical support?

Yes, our experienced team offers technical support and guidance to help you choose the right bearing for your application. We’re also available for after-sales service and maintenance inquiries.

12. How can I place an order?

You can place an order by contacting us through our website, email, or phone. Our sales team will guide you through the process and ensure a seamless transaction.

13. Can I track my shipment?

Yes, once your order is shipped, we will provide a tracking number and details to help you monitor your shipment until it arrives at your destination.

14. What is your return policy?

We accept returns for defective or damaged bearings within a specified timeframe. Please review our return policy or contact our customer service team for assistance.

15. How can I contact you for more information?

You can reach us via email, phone, or through the contact form on our website. Visit our お問い合わせ page for detailed information.

1. Extensive Experience

With over a decade of expertise in the bearing industry, we have established ourselves as a trusted supplier delivering high-quality products to clients worldwide.

2. Premium Quality

Our bearings are manufactured using top-grade materials and cutting-edge technology, ensuring durability, precision, and compliance with international standards like ISO and ANSI.

3. Wide Product Range

We offer a comprehensive selection of bearings, including ball bearings, roller bearings, ceramic bearings, hybrid bearings, and custom-designed solutions to meet the diverse needs of our customers.

4. Customization and OEM Services

We specialize in custom manufacturing and OEM services tailored to your unique requirements. Share your specifications, and we’ll create the perfect solution for your application.

5. Competitive Pricing

As a direct manufacturer, we offer competitive pricing without compromising on quality, ensuring exceptional value for our customers.

6. Global Reach

Our bearings are trusted by clients in Europe, North America, Asia, and beyond. We have a well-established global logistics network to deliver products efficiently and on time.

7. Technical Expertise and Support

Our professional team provides technical guidance to help you select the right bearing for your application. We also offer excellent after-sales support for maintenance and troubleshooting.

8. Strict Quality Control

Every bearing undergoes rigorous testing and inspection to ensure optimal performance and reliability in demanding environments.

9. Environmentally Friendly Manufacturing

We are committed to sustainability, using eco-friendly processes and materials to reduce our environmental impact while maintaining product excellence.

10. Customer-Centric Approach

Your satisfaction is our top priority. We build lasting partnerships with our clients by providing exceptional service, quick responses, and tailored solutions.