6200 Series Deep Groove Ball Bearings are precision-engineered to provide optimal performance in various industrial and commercial applications. These bearings are designed to handle moderate radial and axial loads while offering high-speed capabilities, low noise, and reduced friction. With a robust construction and a range of sealing options, they are suitable for both standard and demanding operating environments.

คุณสมบัติ

- Load Handling: Accommodates moderate radial and axial loads with ease.

- High-Speed Performance: Operates efficiently at high rotational speeds with minimal noise and vibration.

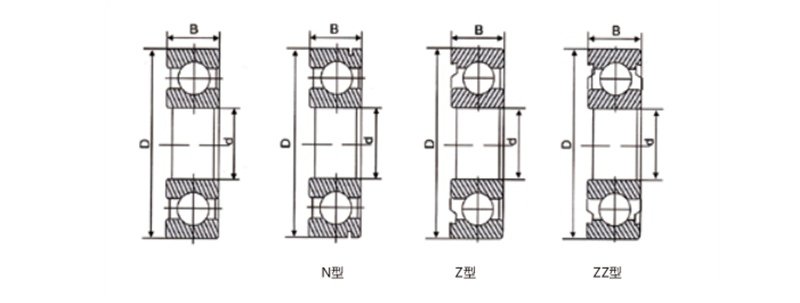

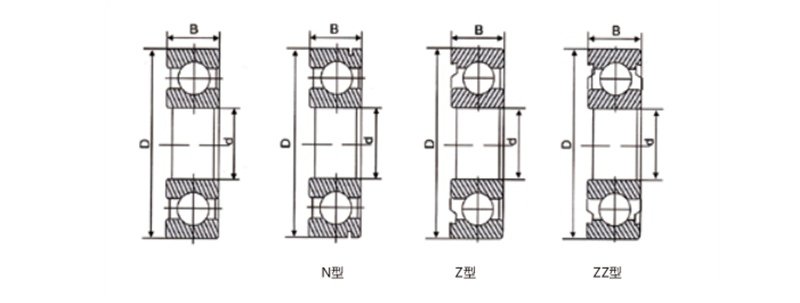

- Multiple Configurations: Available in open, sealed (2RS), and shielded (Z) designs to suit different environments and operational requirements.

- Enhanced Durability: Constructed from high-quality materials to ensure a long service life.

- ความต้านทานการกัดกร่อน: Stainless steel options provide excellent resistance to moisture and harsh conditions.

- Pre-Lubrication: Supplied pre-lubricated with high-quality grease for extended use and reduced maintenance.

การใช้งาน

- Electric motors and generators

- Household appliances (e.g., washing machines, fans)

- HVAC systems and compressors

- Power tools (e.g., drills, saws)

- Automotive components (e.g., alternators, wheel hubs)

- Industrial machinery and conveyor systems

| Bearing Designation |

Dimension(mm) |

Basic load

ratings (kN) |

Speed

ratings(rpm) |

Weight |

| Open |

RS |

ZZ |

d |

D |

B |

rs

min |

Cr |

Cor |

Grease |

Oil |

(Kg) |

| 6200 |

6200

RS |

6200

ZZ |

10 |

30 |

9 |

0.6 |

5.1 |

2.39 |

25000 |

30000 |

0.032 |

| 6201 |

6201

RS |

6201

ZZ |

12 |

32 |

10 |

0.6 |

6.1 |

2.75 |

22000 |

26000 |

0.037 |

| 6202 |

6202

RS |

6202

ZZ |

15 |

35 |

11 |

0.6 |

7.75 |

3.6 |

19000 |

23000 |

0.045 |

| 6203 |

6203

RS |

6203

ZZ |

17 |

40 |

12 |

0.6 |

9.6 |

4.6 |

18000 |

21000 |

0.066 |

| 6204 |

6204

RS |

6204

ZZ |

20 |

47 |

14 |

1 |

12.8 |

6.65 |

16000 |

18000 |

0.106 |

| 6205 |

6205

RS |

6205

ZZ |

25 |

52 |

15 |

1 |

14 |

7.85 |

13000 |

15000 |

0.128 |

| 6206 |

6206

RS |

6206

ZZ |

30 |

62 |

16 |

1 |

19.5 |

11.3 |

11000 |

13000 |

0.199 |

| 6207 |

6207

RS |

6207

ZZ |

35 |

72 |

17 |

1.1 |

25.7 |

15.3 |

9800 |

11000 |

0.288 |

| 6208 |

6208

RS |

6208

ZZ |

40 |

80 |

18 |

1.1 |

29.1 |

17.8 |

8700 |

10000 |

0.366 |

| 6209 |

6209

RS |

6209

ZZ |

45 |

85 |

19 |

1.1 |

32.5 |

20.4 |

7800 |

9200 |

0.398 |

| 6210 |

6210

RS |

6210

ZZ |

50 |

90 |

20 |

1.1 |

35 |

23.2 |

7100 |

8300 |

0.454 |

| 6211 |

6211

RS |

6211

ZZ |

55 |

100 |

21 |

1.5 |

43.5 |

29.2 |

6400 |

7600 |

0.601 |

| 6212 |

6212

RS |

6212

ZZ |

60 |

110 |

22 |

1.5 |

52.5 |

36 |

6000 |

7000 |

0.783 |

| 6213 |

6213

RS |

6213

ZZ |

65 |

120 |

23 |

1.5 |

57.5 |

40 |

5500 |

6500 |

0.99 |

| 6214 |

6214

RS |

6214

ZZ |

70 |

125 |

24 |

1.5 |

62 |

44 |

5100 |

6000 |

1.07 |

| 6215 |

6215

RS |

6215

ZZ |

75 |

130 |

25 |

1.5 |

66 |

49.5 |

4800 |

5600 |

1.18 |

| 6216 |

6216

RS |

6216

ZZ |

80 |

140 |

26 |

2 |

72.5 |

53 |

4500 |

5300 |

1.4 |

| 6217 |

6217

RS |

6217

ZZ |

85 |

150 |

28 |

2 |

83.5 |

64 |

4200 |

5000 |

1.79 |

| 6218 |

6218

RS |

6218

ZZ |

90 |

160 |

30 |

2 |

96 |

71.5 |

4000 |

4700 |

2.15 |

| 6219 |

6219

RS |

6219

ZZ |

95 |

170 |

32 |

2.1 |

109 |

82 |

3700 |

4400 |

2.62 |

| 6220 |

6220

RS |

6220

ZZ |

100 |

180 |

34 |

2.1 |

122 |

93 |

3500 |

4200 |

3.14 |

| 6221 |

6221

RS |

6221

ZZ |

105 |

190 |

36 |

2.1 |

133 |

105 |

3400 |

4000 |

3.7 |

| 6222 |

6222

RS |

6222

ZZ |

110 |

200 |

38 |

2.1 |

144 |

117 |

3200 |

3800 |

4.36 |

| 6224 |

6224

RS |

6224

ZZ |

120 |

215 |

40 |

2.1 |

155 |

131 |

2900 |

3400 |

5.15 |

| 6228 |

6228

RS |

6228

ZZ |

140 |

250 |

42 |

3 |

166 |

150 |

2500 |

2900 |

7.57 |

| 6232 |

6232

RS |

6232

ZZ |

160 |

290 |

48 |

3 |

185 |

186 |

2100 |

2500 |

11.7 |

| 6234 |

6234

RS |

6234

ZZ |

170 |

310 |

52 |

4 |

212 |

223 |

20000 |

2400 |

14.5 |

| 6236 |

6236

RS |

6236

ZZ |

180 |

320 |

52 |

4 |

227 |

241 |

19000 |

22000 |

15.1 |

| 6238 |

6238

RS |

6238

ZZ |

190 |

340 |

55 |

4 |

255 |

281 |

18000 |

21000 |

18.2 |

| 6244 |

6244

RS |

6244

ZZ |

220 |

400 |

65 |

4 |

297 |

365 |

15000 |

18000 |

30.2 |

| 62/22 |

62/22

RS |

62/22

ZZ |

22 |

50 |

14 |

1 |

1320 |

690 |

14000 |

17000 |

0.117 |

| 62/28 |

62/28

RS |

62/28

ZZ |

28 |

58 |

16 |

1 |

1830 |

995 |

12000 |

14000 |

0.171 |

| 62/32 |

62/32

RS |

62/32

ZZ |

32 |

65 |

17 |

1 |

2110 |

1190 |

11000 |

12000 |

0.226 |

1. What types of bearings do you offer?

We provide a wide range of bearings, including ball bearings, roller bearings, deep groove ball bearings, angular contact bearings, cylindrical roller bearings, self-aligning bearings, thrust bearings, needle bearings, and more. We also specialize in ceramic, hybrid, and custom-designed bearings.

2. คุณมีบริการตลับลูกปืนแบบกำหนดเองหรือไม่?

ใช่, เรามีบริการผลิตตลับลูกปืน OEM และแบบกำหนดเองที่ปรับให้เหมาะกับความต้องการเฉพาะของคุณ. แชร์ความต้องการของคุณกับเรา, และทีมผู้เชี่ยวชาญของเราจะช่วยคุณออกแบบและผลิตโซลูชันตลับลูกปืนที่สมบูรณ์แบบ.

3. ตลับลูกปืนของคุณใช้วัสดุอะไรบ้าง?

ตลับลูกปืนของเราผลิตจากวัสดุคุณภาพสูง เช่น Gcr15, สแตนเลส (304, 316, 440C), ซิลิคอนไนไตรด์ (Si3N4), เซอร์โคเนีย (ZrO₂), PEEK, PTFE, และวัสดุขั้นสูงอื่น ๆ เพื่อให้มั่นใจในความทนทาน, ความแม่นยำ, และความเชื่อถือได้ในแอปพลิเคชันต่าง ๆ.

4. คุณสามารถให้ตัวอย่างก่อนสั่งซื้อจำนวนมากได้หรือไม่?

ใช่, เรามีตลับลูกปืนตัวอย่างสำหรับการทดสอบและประเมินผล. โปรดติดต่อเราพร้อมคำขอตัวอย่างของคุณ, และเรายินดีที่จะให้ความช่วยเหลือ.

5. คุณให้บริการในอุตสาหกรรมใดบ้าง?

เราดูแลลูกค้าที่หลากหลายอุตสาหกรรม, รวมถึงยานยนต์, การบินและอวกาศ, การเกษตร, เครื่องจักร, การแปรรูปอาหาร, อุปกรณ์ทางการแพทย์, ระบบอัตโนมัติในอุตสาหกรรม, และพลังงานหมุนเวียน.

6. คุณส่งออกสินค้าหรือไม่?

ใช่, เราส่งออกแบริ่งไปทั่วโลก, รวมถึงยุโรป, อเมริกาเหนือ, เอเชีย, และภูมิภาคอื่น ๆ. สินค้าของเราปฏิบัติตามมาตรฐานคุณภาพสากลและได้รับการตอบรับที่ดีจากลูกค้าทั่วโลก.

7. ปริมาณสั่งซื้อขั้นต่ำของคุณคือเท่าไหร่ (MOQ)?

ปริมาณสั่งซื้อขั้นต่ำของเราจะแตกต่างกันไปตามประเภทของสินค้าและความต้องการปรับแต่ง. สำหรับสินค้ามาตรฐาน, เรามีตัวเลือก MOQ ที่ยืดหยุ่น. ติดต่อเราเพื่อดูรายละเอียดที่เหมาะสมกับความต้องการของคุณ.

8. ระยะเวลาในการผลิตของคุณคือเท่าไหร่?

ระยะเวลาในการผลิตขึ้นอยู่กับประเภทของแบริ่งและปริมาณการสั่งซื้อ. แบริ่งมาตรฐานมักพร้อมสำหรับการจัดส่งภายใน 2-4 สัปดาห์, ในขณะที่คำสั่งซื้อที่ปรับแต่งอาจใช้เวลานานกว่า. เราพยายามจัดส่งคำสั่งซื้ออย่างรวดเร็วเพื่อให้ตรงตามกำหนดเวลาของคุณ.

9. คุณมั่นใจคุณภาพสินค้าของคุณได้อย่างไร?

ตลับลูกปืนของเราผลิตภายใต้การควบคุมคุณภาพอย่างเข้มงวด, รวมถึงการรับรองมาตรฐาน ISO, การทดสอบความแม่นยำ, และการตรวจสอบอย่างเข้มงวด. แต่ละผลิตภัณฑ์จะถูกทดสอบเพื่อให้มั่นใจว่าตรงตามมาตรฐานสากล.

10. คุณรับวิธีชำระเงินแบบใดบ้าง?

เรารับหลายวิธีการชำระเงิน, รวมถึงการโอนเงินผ่านธนาคาร (T/T), PayPal, และบัตรเครดิต. ติดต่อทีมขายของเราเพื่อขอความช่วยเหลือเพิ่มเติมเกี่ยวกับตัวเลือกการชำระเงิน.

11. คุณมีบริการสนับสนุนทางเทคนิคหรือไม่?

ใช่, ทีมงานที่มีประสบการณ์ของเรามีบริการสนับสนุนทางเทคนิคและคำแนะนำเพื่อช่วยให้คุณเลือกตลับลูกปืนที่เหมาะสมกับการใช้งาน. เรายังพร้อมให้บริการหลังการขายและสอบถามเกี่ยวกับการบำรุงรักษา.

12. ฉันสามารถสั่งซื้อได้อย่างไร?

คุณสามารถสั่งซื้อได้โดยการติดต่อเราผ่านเว็บไซต์, อีเมล, หรือโทรศัพท์. ทีมขายของเราจะนำคุณผ่านกระบวนการและรับประกันการทำธุรกรรมที่ราบรื่น.

13. Can I track my shipment?

ใช่, once your order is shipped, we will provide a tracking number and details to help you monitor your shipment until it arrives at your destination.

14. What is your return policy?

เรายอมรับการคืนสินค้าสำหรับตลับลูกปืนที่ชำรุดหรือเสียหายในช่วงเวลาที่กำหนด. โปรดตรวจสอบนโยบายการคืนสินค้าของเราหรือ ติดต่อฝ่ายบริการลูกค้า สำหรับความช่วยเหลือ.

15. ฉันสามารถติดต่อคุณเพื่อขอข้อมูลเพิ่มเติมได้อย่างไร?

คุณสามารถติดต่อเราทางอีเมล, โทรศัพท์, หรือผ่านแบบฟอร์มติดต่อบนเว็บไซต์ของเรา. เยี่ยมชมหน้าของเรา ติดต่อเรา สำหรับข้อมูลรายละเอียด.

1. ประสบการณ์ที่กว้างขวาง

ด้วยประสบการณ์มากกว่าหนึ่งทศวรรษในอุตสาหกรรมตลับลูกปืน, เราจึงได้สร้างชื่อเสียงในฐานะผู้จัดจำหน่ายที่เชื่อถือได้ ส่งมอบผลิตภัณฑ์คุณภาพสูงให้กับลูกค้าทั่วโลก.

2. คุณภาพพรีเมียม

ตลับลูกปืนของเราผลิตจากวัสดุชั้นดีและเทคโนโลยีล้ำสมัย, รับรองความทนทาน, ความแม่นยำ, และเป็นไปตามมาตรฐานสากลเช่น ISO และ ANSI.

3. ผลิตภัณฑ์หลากหลาย

เรามีชุดตลับลูกปืนให้เลือกอย่างครบถ้วน, including ball bearings, roller bearings, ตลับลูกปืนเซรามิก, ตลับลูกปืนไฮบริด, และโซลูชันที่ออกแบบตามความต้องการเฉพาะเพื่อรองรับความต้องการที่หลากหลายของลูกค้า.

4. บริการปรับแต่งและ OEM

เรามีความเชี่ยวชาญในการผลิตตามสั่งและบริการ OEM ที่ปรับให้เหมาะกับความต้องการเฉพาะของคุณ. แชร์ข้อกำหนดของคุณ, และเราจะสร้างโซลูชันที่สมบูรณ์แบบสำหรับการใช้งานของคุณ.

5. ราคาที่แข่งขันได้

ในฐานะผู้ผลิตโดยตรง, เรานำเสนอราคาที่แข่งขันได้โดยไม่ลดทอนคุณภาพ, รับประกันคุณค่าอย่างยอดเยี่ยมให้กับลูกค้าของเรา.

6. ขอบเขตทั่วโลก

ตลับลูกปืนของเราได้รับความไว้วางใจจากลูกค้าในยุโรป, อเมริกาเหนือ, เอเชีย, และทั่วโลก. เรามีเครือข่ายโลจิสติกส์ทั่วโลกที่มั่นคงเพื่อส่งมอบผลิตภัณฑ์อย่างมีประสิทธิภาพและตรงเวลา.

7. ความเชี่ยวชาญและการสนับสนุนทางเทคนิค

ทีมงานมืออาชีพของเราให้คำแนะนำทางเทคนิคเพื่อช่วยคุณในการเลือกแบริ่งที่เหมาะสมกับการใช้งานของคุณ. เรายังมีบริการสนับสนุนหลังการขายที่ยอดเยี่ยมสำหรับการบำรุงรักษาและการแก้ไขปัญหา.

8. การควบคุมคุณภาพอย่างเคร่งครัด

แบริ่งทุกชิ้นผ่านการทดสอบและตรวจสอบอย่างเข้มงวดเพื่อให้มั่นใจในประสิทธิภาพและความน่าเชื่อถือสูงสุดในสภาพแวดล้อมที่ท้าทาย.

9. การผลิตที่เป็นมิตรต่อสิ่งแวดล้อม

เราให้ความสำคัญกับความยั่งยืน, ใช้กระบวนการและวัสดุที่เป็นมิตรกับสิ่งแวดล้อมเพื่อลดผลกระทบต่อสิ่งแวดล้อมในขณะเดียวกันก็รักษาคุณภาพของผลิตภัณฑ์.

10. แนวทางที่เน้นลูกค้าเป็นศูนย์กลาง

ความพึงพอใจของคุณคือสิ่งสำคัญที่สุดสำหรับเรา. เราสร้างความสัมพันธ์ที่ยั่งยืนกับลูกค้าของเราผ่านการให้บริการที่ยอดเยี่ยม, การตอบสนองอย่างรวดเร็ว, และโซลูชั่นที่ปรับแต่งเฉพาะตัว.