Cel 29400 Series Thrust Spherical Roller Bearings are designed to handle extremely high axial loads while accommodating misalignment, making them suitable for demanding industrial applications. Featuring a self-aligning design with spherical rollers, these bearings offer excellent load distribution, high durability, and reliable performance in heavy-duty systems.

Caracteristici:

- Design cu role sferice: Provides optimal load distribution and supports high axial and moderate radial loads.

- Capacitate de autoaliniere: Compensates for shaft deflections and misalignments, ensuring consistent operation.

- Capacitate mare de încărcare: Engineered to handle extreme axial loads in tough working environments.

- Construcție durabilă: Manufactured from premium-grade steel for long service life and resistance to wear.

- Funcționare cu frecare redusă: Precision cage design reduces friction and heat generation for efficient performance.

- Advanced Lubrication System: Grooved raceways facilitate smooth lubrication flow for extended bearing life.

- Robust Cage Design: Ensures roller stability and reliable alignment under dynamic loads.

Aplicaţii:

- Steel Industry: Perfect for rolling mills, convertizoare, și mașini de turnare continuă.

- Power Plants: Commonly used in turbines and heavy mechanical systems.

- Echipamente Miniere: Ideal for crushers, heavy-duty conveyors, and mining machinery.

- Marine Systems: Reliable in ship propulsion systems and deck machinery.

- Construction Equipment: Suitable for use in cranes, excavators, and other high-load machinery.

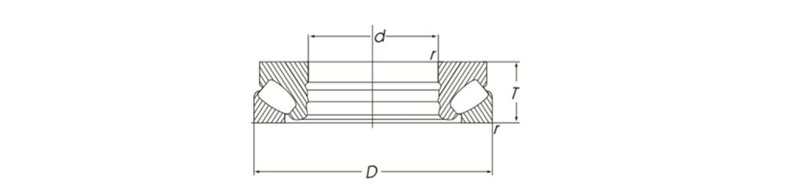

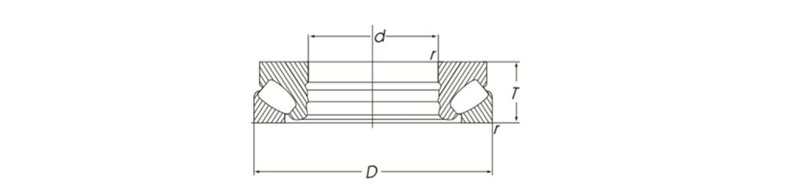

| Model Lagăr |

Dimensiuni(milimetru) |

Capacitate de Sarcină de Bază(KN) |

Greutate(kg) |

| d |

D |

T |

Dyn.C |

Stat.Co |

| 29412 |

60 |

130 |

42 |

390 |

915 |

2.61 |

| 29413 |

65 |

140 |

45 |

455 |

1080 |

3.34 |

| 29414 |

70 |

150 |

48 |

520 |

1250 |

4.06 |

| 29415 |

75 |

160 |

51 |

600 |

1430 |

4.760 |

| 29416 |

80 |

170 |

54 |

670 |

1630 |

5.91 |

| 29417 |

85 |

180 |

58 |

735 |

1800 |

7.04 |

| 29418 |

90 |

190 |

60 |

590 |

1700 |

8.18 |

| 29420 |

100 |

210 |

67 |

700 |

2000 |

11.2 |

| 29422 |

110 |

230 |

73 |

840 |

2600 |

14.7 |

| 29424 |

120 |

250 |

78 |

950 |

3280 |

18.2 |

| 29426 |

130 |

270 |

85 |

1100 |

3400 |

22.8 |

| 29428 |

140 |

280 |

85 |

1100 |

3500 |

24.6 |

| 29430 |

150 |

300 |

90 |

1300 |

4100 |

29.9 |

| 29432 |

160 |

320 |

95 |

1500 |

5000 |

36.2 |

| 29434 |

170 |

340 |

103 |

1800 |

5900 |

44.3 |

| 29436 |

180 |

360 |

109 |

1900 |

6200 |

52.6 |

| 29438 |

190 |

380 |

115 |

2100 |

7000 |

60.7 |

| 29440 |

200 |

400 |

122 |

2260 |

7900 |

72.2 |

| 29444 |

220 |

420 |

122 |

2300 |

8350 |

74.9 |

| 29448 |

240 |

440 |

122 |

2600 |

9300 |

80 |

| 29452 |

260 |

480 |

132 |

2800 |

11000 |

104 |

| 29456 |

280 |

520 |

145 |

3300 |

14000 |

124 |

| 29460 |

300 |

540 |

145 |

3000 |

14500 |

140 |

1. Ce tipuri de rulmenți oferiți?

Oferim o gamă largă de rulmenți, inclusiv rulmenți cu bile, rulmenți cu role, rulmenți adânci cu bile, rulmenți cu contact unghiular, rulmenți cu role cilindrice, rulmenți cu auto-aliniere, rulmenți axiali, rulmenți cu ace, și multe altele. De asemenea, suntem specializați în ceramică, Hibrid, și rulmenți proiectați la comandă.

2. Oferiți soluții personalizate de rulmenți?

Da, oferim servicii de producție de rulmenți OEM și personalizate, adaptate nevoilor dumneavoastră specifice. Împărtășiți-vă cerințele cu noi, iar echipa noastră de experți vă va ajuta să proiectați și să fabricați soluția perfectă de rulmenți.

3. Ce materiale sunt utilizate în rulmenții dvs.?

Rulmenții noștri sunt fabricați folosind materiale de înaltă calitate, cum ar fi Gcr15, oțel inoxidabil (304, 316, 440C), Nitrură de siliciu (Si3N4), Zirconiu (ZrO₂), PEEK, PTFE, și alte materiale avansate pentru a asigura durabilitatea, precizie, și fiabilitate în diverse aplicații.

4. Puteți furniza mostre înainte de a plasa o comandă în vrac?

Da, Oferim mostre de rulmenți pentru testare și evaluare. Vă rugăm să ne contactați cu cererea dvs., și vom fi bucuroși să vă ajutăm.

5. Ce industrii deserviți?

Ne adresăm unei game diverse de industrii, inclusiv auto, Aerospace, agricultură, mașinărie, Prelucrarea alimentelor, echipamente medicale, automatizare industrială, și energia regenerabilă.

6. Exportați produsele dvs.?

Da, Exportăm rulmenți în întreaga lume, inclusiv în Europa, America de Nord, Asia, și alte regiuni. Produsele noastre respectă standardele internaționale de calitate și au fost bine primite de clienții din întreaga lume.

7. Care este cantitatea minimă de comandă (MOQ)?

MOQ-ul nostru variază în funcție de tipul de produs și de cerințele de personalizare. Pentru produse standard, oferim opțiuni MOQ flexibile. Contactați-ne pentru detalii specifice nevoilor dumneavoastră.

8. Care este timpul de producție?

Timpii de livrare depind de tipul de rulment și de cantitatea comenzii. Rulmenții standard sunt de obicei gata de expediere în 2-4 Săptămâni, în timp ce comenzile personalizate pot dura mai mult. Ne străduim să livrăm comenzile cu promptitudine pentru a vă respecta termenele limită.

9. Cum asigurați calitatea produsului?

Rulmenții noștri sunt fabricați sub măsuri stricte de control al calității, inclusiv certificări ISO, Testare de precizie, și inspecții riguroase. Fiecare produs este testat pentru a asigura conformitatea cu standardele internaționale.

10. Ce metode de plată acceptați?

Acceptăm mai multe metode de plată, inclusiv transfer bancar (T / T), PayPal, și carduri de credit. Contactați echipa noastră de vânzări pentru asistență suplimentară cu privire la opțiunile de plată.

11. Oferiți asistență tehnică?

Da, Echipa noastră experimentată oferă asistență tehnică și îndrumare pentru a vă ajuta să alegeți rulmentul potrivit pentru aplicația dvs.. De asemenea, suntem disponibili pentru servicii post-vânzare și întrebări de întreținere.

12. Cum pot plasa o comandă?

Puteți plasa o comandă contactându-ne prin intermediul site-ului nostru web, E-mail, sau telefon. Echipa noastră de vânzări vă va ghida pe parcursul procesului și vă va asigura o tranzacție fără probleme.

13. Îmi pot urmări expedierea?

Da, odată ce comanda este expediată, Vă vom oferi un număr de urmărire și detalii pentru a vă ajuta să vă monitorizați expedierea până când ajunge la destinație.

14. Care este politica ta de returnare?

Acceptăm retururi pentru rulmenți defecti sau deteriorați într-un interval de timp specificat. Vă rugăm să consultați politica noastră de returnare sau să contactați echipa noastră de servicii pentru clienți pentru asistență.

15. Cum vă pot contacta pentru mai multe informații?

Ne puteți contacta prin e-mail, Telefon, sau prin intermediul formularului de contact de pe site-ul nostru. Vizitați Contactați-ne pentru informații detaliate.

1. Experiență vastă

Cu peste un deceniu de expertiză în industria rulmenților, Ne-am impus ca un furnizor de încredere care livrează produse de înaltă calitate clienților din întreaga lume.

2. Calitate premium

Rulmenții noștri sunt fabricați folosind materiale de top și tehnologie de ultimă oră, asigurarea durabilității, precizie, și conformitatea cu standardele internaționale precum ISO și ANSI.

3. Gamă largă de produse

Oferim o selecție cuprinzătoare de rulmenți, inclusiv rulmenți cu bile, rulmenți cu role, rulmenți ceramici, rulmenți hibrizi, și soluții personalizate pentru a satisface nevoile diverse ale clienților noștri.

4. Personalizare și servicii OEM

Suntem specializați în producție personalizată și servicii OEM adaptate cerințelor dumneavoastră unice. Partajați-vă specificațiile, Și vom crea soluția perfectă pentru aplicația ta.

5. Prețuri competitive

Ca producător direct, Oferim prețuri competitive fără a compromite calitatea, asigurarea unei valori excepționale pentru clienții noștri.

6. Acoperire globală

Rulmenții noștri sunt de încredere pentru clienții din Europa, America de Nord, Asia, și nu numai. Avem o rețea logistică globală bine stabilită pentru a livra produsele eficient și la timp.

7. Expertiză tehnică și asistență

Echipa noastră de profesioniști oferă îndrumare tehnică pentru a vă ajuta să selectați rulmentul potrivit pentru aplicația dvs.. Oferim, de asemenea, asistență post-vânzare excelentă pentru întreținere și depanare.

8. Control strict al calității

Fiecare rulment este supus unor teste și inspecții riguroase pentru a asigura performanțe și fiabilitate optime în medii solicitante.

9. Producție ecologică

Suntem dedicați sustenabilității, utilizarea proceselor și materialelor ecologice pentru a reduce impactul asupra mediului, menținând în același timp excelența produselor.

10. Abordare centrată pe client

Satisfacția dumneavoastră este prioritatea noastră principală. Construim parteneriate de durată cu clienții noștri oferind servicii excepționale, Răspunsuri rapide, și soluții personalizate.