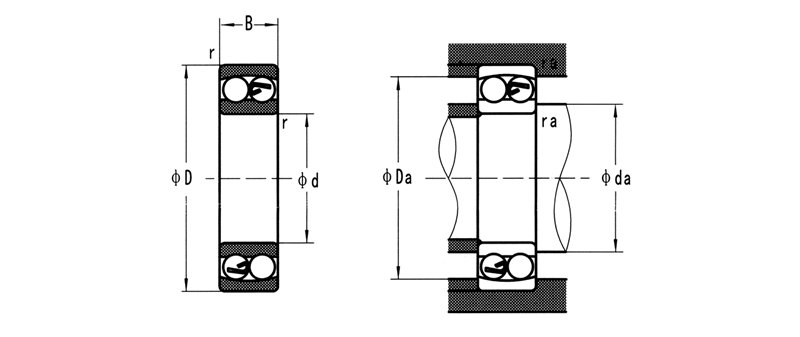

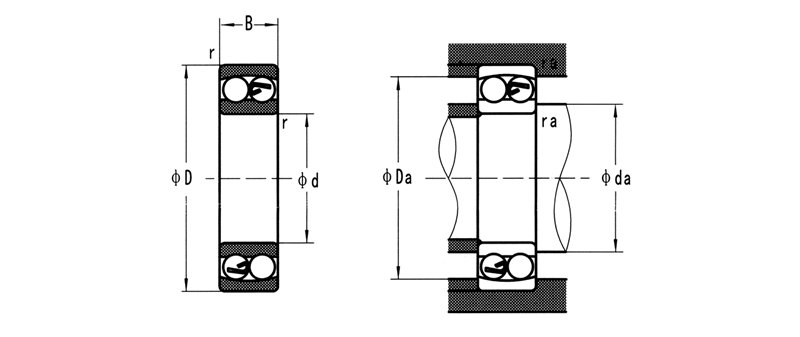

1200 Series Self-Aligning Ball Bearings are designed to accommodate misalignment and radial loads, providing excellent performance even when the shaft and housing are not perfectly aligned. These bearings feature two rows of balls and a common concave raceway in the outer ring, which allows them to self-align and handle angular misalignments. Ideal for applications where shaft alignment is difficult to maintain, these bearings provide long-lasting, reliable operation.

Características

- Self-Aligning: Can tolerate angular misalignment of up to 3° between the shaft and housing.

- Dual Row Balls: Two rows of balls for higher load carrying capacity.

- Robust Performance: Handles both radial and axial loads.

- Low Friction: Ensures smooth operation and minimizes wear.

- Sealed or Shielded Options: Prevents contamination and reduces maintenance needs.

- Durable Design: Made from high-quality materials for long service life.

Aplicações

- Agricultural machinery

- Textile machinery

- Conveyor systems

- Automotive applications

- Industrial pumps

- Fans and blowers

- Robotics and automation systems

| NO. |

BASIc SIZE |

LOAD RATING(kN) |

MAX SPEED(rmin) |

WEIGHT |

Set Sleeve And

Release Sleeve |

| d |

D |

B |

DYNAMIC |

STATIC |

GREASE |

OIL |

(KG) |

1204

1204K |

20 |

47 |

14 |

12.4 |

32 |

13000 |

15000 |

0.119 |

|

| 20 |

47 |

14 |

0.119 |

H204AH204 |

1205

1205K |

25 |

52 |

15 |

14 |

4.05 |

11000 |

13000 |

0.144 |

|

| 25 |

52 |

15 |

0.141 |

H205AH205 |

1206

1206K |

30 |

62 |

16 |

15.6 |

5.85 |

9200 |

11000 |

0.226 |

|

| 30 |

62 |

16 |

0.222 |

H206AH206 |

1207

1207K |

35 |

72 |

17 |

18.6 |

6.7 |

8000 |

9400 |

0.318 |

|

| 35 |

72 |

17 |

0.318 |

H207AH207 |

1208

1208K |

40 |

80 |

18 |

19.5 |

8.65 |

7100 |

8400 |

0.411 |

|

| 40 |

80 |

18 |

0.41 |

H208AH208 |

1209

1209K |

45 |

85 |

19 |

22.4 |

9.65 |

6400 |

7500 |

0.49 |

|

| 45 |

85 |

19 |

0.485 |

H209AH209 |

1210

1210K |

50 |

90 |

20 |

26 |

10.8 |

5800 |

6800 |

0.545 |

|

| 50 |

90 |

20 |

0.485 |

H210AH210 |

1211

1211K |

55 |

100 |

21 |

27 |

13.4 |

5300 |

6200 |

0.722 |

|

| 55 |

100 |

21 |

0.709 |

H211AH211 |

1212

1212K |

60 |

110 |

22 |

302 |

15.6 |

4900 |

5800 |

0.895 |

|

| 60 |

110 |

22 |

0.877 |

H212AH212 |

1213

1213K |

65 |

120 |

23 |

35.1 |

14 |

4500 |

5300 |

0.92 |

|

| 65 |

120 |

23 |

0.9 |

H213AH213 |

1214

1214K |

70 |

125 |

24 |

35.8 |

14.6 |

4200 |

4900 |

1.29 |

|

| 70 |

125 |

24 |

1.26 |

H214AH214 |

1215

1215K |

75 |

130 |

25 |

39 |

15.6 |

3900 |

4600 |

1.35 |

|

| 75 |

130 |

25 |

1.3 |

H215AH215 |

1216

1216K |

80 |

140 |

26 |

39.7 |

17 |

3700 |

4300 |

1.6 |

|

| 80 |

140 |

26 |

1.69 |

H216AH216 |

1217

1217K |

85 |

150 |

28 |

48.8 |

20.8 |

3500 |

4100 |

2.1 |

|

| 85 |

150 |

28 |

2.07 |

H217AH217 |

1218

1218K |

90 |

160 |

30 |

572 |

23.6 |

3300 |

3800 |

2.44 |

|

| 90 |

160 |

30 |

2.4 |

H218AH218 |

1219

1219K |

95 |

170 |

32 |

63.7 |

27 |

3100 |

3600 |

3.06 |

|

| 95 |

170 |

32 |

3.02 |

H219AH219 |

1220

1220K |

100 |

180 |

34 |

68.9 |

30 |

2900 |

3400 |

3.7 |

|

| 100 |

180 |

34 |

3.67 |

H220AH220 |

1222

1222K |

110 |

200 |

38 |

88.4 |

39 |

2600 |

3100 |

5.2 |

|

| 110 |

200 |

38 |

5.12 |

H222AH222 |

1. What types of bearings do you offer?

We provide a wide range of bearings, including ball bearings, roller bearings, deep groove ball bearings, angular contact bearings, rolamentos de rolos cilíndricos, rolamentos auto-alinhantes, rolamentos de impulso, rolamentos de agulhas, e mais. Também nos especializamos em rolamentos cerâmicos, híbridos, e rolamentos personalizados.

2. Vocês oferecem soluções personalizadas de rolamentos??

Sim, fornecemos serviços de produção de rolamentos OEM e personalizados adaptados às suas necessidades específicas. Partilhe os seus requisitos connosco, e a nossa equipa de especialistas ajudará a conceber e fabricar a solução de rolamento perfeita.

3. Que materiais são utilizados nos seus rolamentos??

Os nossos rolamentos são fabricados com materiais de alta qualidade, como GCr15, aço inoxidável (304, 316, 440C), nitreto de silício (Si3N4), zircónia (ZrO₂), PEEK, PTFE, e outros materiais avançados para garantir durabilidade, precisão, e fiabilidade em diversas aplicações.

4. Podem fornecer amostras antes de fazer uma encomenda em grande quantidade??

Sim, oferecemos rolamentos de amostra para testes e avaliação. Por favor, contacte-nos com o seu pedido de amostra, e teremos todo o prazer em ajudá-lo.

5. Que indústrias atendem?

Atendemos a uma ampla variedade de indústrias, incluindo automóvel, aeronáutica, agricultura, maquinaria, processamento de alimentos, equipamentos médicos, automação industrial, e energia renovável.

6. Vocês exportam os vossos produtos?

Sim, exportamos rolamentos para todo o mundo, incluindo para a Europa, América do Norte, Ásia, e outras regiões. Os nossos produtos cumprem os padrões de qualidade internacionais e têm sido bem recebidos pelos clientes globalmente.

7. Qual é a quantidade mínima de encomenda (QME)?

A nossa quantidade mínima de encomenda varia consoante o tipo de produto e os requisitos de personalização. Para produtos standard, oferecemos opções de QME flexíveis. Contacte-nos para detalhes específicos para as suas necessidades.

8. Qual é o tempo de produção?

Os prazos de produção dependem do tipo de rolamento e da quantidade encomendada. Os rolamentos standard estão normalmente prontos para expedição dentro de 2-4 semanas, Embora as encomendas personalizadas possam demorar mais tempo. Esforçamo-nos por entregar as encomendas pontualmente para cumprir os seus prazos.

9. Como garantem a qualidade do produto?

Os nossos rolamentos são fabricados sob rigorosas medidas de controlo de qualidade, incluindo certificações ISO, testes de precisão, e inspeções rigorosas. Cada produto é testado para garantir a conformidade com as normas internacionais.

10. Que métodos de pagamento aceitam?

Aceitamos múltiplos métodos de pagamento, incluindo transferência bancária (T/T), PayPal, e cartões de crédito. Contacte a nossa equipa de vendas para assistência adicional relativamente às opções de pagamento.

11. Fornecem suporte técnico?

Sim, A nossa equipa experiente oferece suporte técnico e orientação para ajudá-lo a escolher o rolamento adequado para a sua aplicação. Estamos também disponíveis para serviços pós-venda e consultas de manutenção.

12. Como posso fazer uma encomenda?

You can place an order by contacting us through our website, email, or phone. Our sales team will guide you through the process and ensure a seamless transaction.

13. Can I track my shipment?

Sim, once your order is shipped, we will provide a tracking number and details to help you monitor your shipment until it arrives at your destination.

14. What is your return policy?

We accept returns for defective or damaged bearings within a specified timeframe. Please review our return policy or contact our customer service team for assistance.

15. How can I contact you for more information?

You can reach us via email, phone, or through the contact form on our website. Visit our Contact Us page for detailed information.

1. Extensive Experience

With over a decade of expertise in the bearing industry, estabelecemo-nos como um fornecedor de confiança, fornecendo produtos de alta qualidade a clientes em todo o mundo.

2. Qualidade Premium

Os nossos rolamentos são fabricados utilizando materiais de primeira qualidade e tecnologia de ponta, garantindo durabilidade, precisão, e conformidade com normas internacionais como ISO e ANSI.

3. Ampla Gama de Produtos

Oferecemos uma seleção abrangente de rolamentos, including ball bearings, roller bearings, rolamentos cerâmicos, rolamentos híbridos, e soluções personalizadas para atender às diversas necessidades dos nossos clientes.

4. Serviços de Personalização e OEM

Especializamo-nos em fabrico personalizado e serviços OEM adaptados aos seus requisitos únicos. Partilhe as suas especificações, e criaremos a solução perfeita para a sua aplicação.

5. Preços Competitivos

Como fabricante direto, oferecemos preços competitivos sem comprometer a qualidade, garantindo um valor excecional para os nossos clientes.

6. Alcance Global

Our bearings are trusted by clients in Europe, América do Norte, Ásia, and beyond. Temos uma rede logística global bem estabelecida para entregar produtos de forma eficiente e pontual.

7. Especialização Técnica e Suporte

A nossa equipa profissional fornece orientação técnica para ajudá-lo a selecionar o rolamento certo para a sua aplicação. Também oferecemos um excelente suporte pós-venda para manutenção e resolução de problemas.

8. Controlo de Qualidade Rigoroso

Cada rolamento passa por testes e inspeções rigorosos para garantir um desempenho e fiabilidade ótimos em ambientes exigentes.

9. Fabrico Ecológico

Estamos comprometidos com a sustentabilidade, utilizando processos e materiais ecológicos para reduzir o nosso impacto ambiental, mantendo a excelência do produto.

10. Abordagem Centrada no Cliente

A sua satisfação é a nossa maior prioridade. Construímos parcerias duradouras com os nossos clientes ao fornecer um serviço excecional, respostas rápidas, e soluções personalizadas.