NA Series Radial Insert Ball Bearings are specifically engineered for applications requiring reliable radial load handling and easy mounting. Designed with a bearing insert housed in robust units, these bearings are known for their efficiency, durabilidad, and adaptability across diverse operational conditions. They are widely utilized in industries requiring high precision and performance.

Características

- Enhanced Durability: Made from high-quality materials for longevity and resistance to wear.

- Corrosion-Resistant Options: Stainless steel options are available for harsh or moisture-prone environments.

- Effective Sealing: Equipped with robust seals to prevent contamination and ensure smooth operation.

- Flexible Locking Mechanisms: Includes set screws or eccentric locking collars for secure mounting.

- Versatile Housing Compatibility: Suitable for pillow block, flange units, and other standard housings.

- Pre-Lubricated Design: Supplied with high-performance grease for immediate use.

Aplicaciones

- Agricultural machinery

- Conveyor and material handling systems

- Textile machinery

- Packaging equipment

- HVAC systems

- Componentes automotrices

Bearing

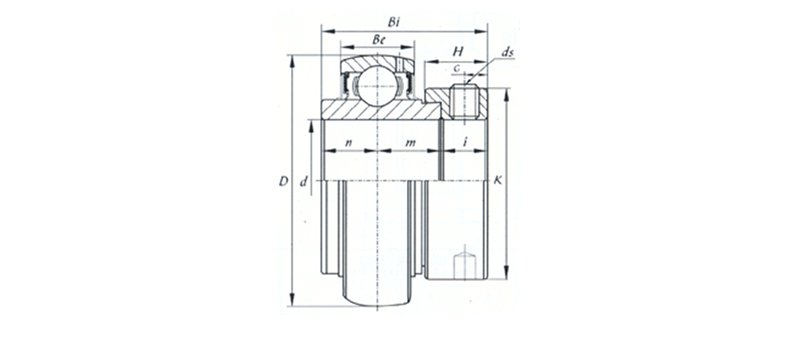

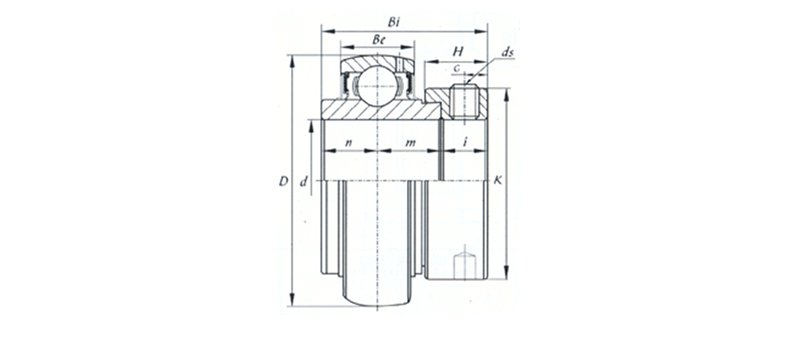

No. |

d |

Dimensiones(mm) |

Basic Load

Rating (KN) |

| (mm) |

(in.) |

D |

Be |

Bi |

B1 |

n |

K |

H |

G |

ds |

Dinámico |

Estática |

| NA203 |

17 |

|

40 |

14 |

37.3 |

27.8 |

13.9 |

28.6 |

13.5 |

5 |

M6X1 |

900 |

500 |

| NA203-11 |

17.463 |

11/16 |

40 |

14 |

37.3 |

27.8 |

13.9 |

28.6 |

13.5 |

5 |

1/4-28UNF |

900 |

500 |

| NA204-12 |

19.05 |

3/4 |

47 |

17 |

43.7 |

34.2 |

17. |

33.3 |

13.5 |

5 |

1/4-28UNF |

1250 |

650 |

| NA204 |

20 |

|

47 |

17 |

43.7 |

34.2 |

17.1 |

33.3 |

13.5 |

5 |

M6X1 |

1250 |

650 |

| NA205-14 |

22.225 |

7/8 |

52 |

17 |

44.4 |

35 |

17.5 |

38.1 |

13.5 |

5 |

1/4-28UNF |

1400 |

750 |

| NA205-15 |

23.813 |

15/16 |

52 |

17 |

44.4 |

35 |

17.5 |

38.1 |

13.5 |

5 |

1/4-28UNF |

1400 |

750 |

| NA205 |

25 |

|

52 |

17 |

44.4 |

35 |

17.5 |

38.1 |

13.5 |

5 |

M6x1 |

1400 |

750 |

| NA205-16 |

25.4 |

1 |

52 |

17 |

44.4 |

35 |

17.5 |

38.1 |

13.5 |

5 |

1/4-28UNF |

1400 |

750 |

| NA206-18 |

28.575 |

11/8 |

62 |

19 |

48.4 |

36.6 |

18.3 |

44.5 |

15.9 |

6 |

5/16-24UNF |

1900 |

1100 |

| NA206 |

30 |

|

62 |

19 |

48.4 |

36.6 |

18.3 |

44.5 |

15.9 |

6 |

M8x1 |

1900 |

1100 |

| NA206-19 |

30.163 |

1

3/16 |

62 |

19 |

48.4 |

36.6 |

18.3 |

44.5 |

15.9 |

6 |

5/16-24UNF |

1900 |

1100 |

| NA206-20 |

31.75 |

11/4 |

62 |

19 |

48.4 |

36.6 |

18.3 |

44.5 |

15.9 |

6 |

5/16-24UNF |

1900 |

1100 |

| NA207-20 |

31.75 |

11/4 |

72 |

20 |

51.1 |

37.6 |

18.8 |

55.6 |

17.5 |

6.5 |

5/16-24UNF |

2550 |

1500 |

| NA207-22 |

34.925 |

13/8 |

72 |

20 |

51.1 |

37.6 |

18.8 |

55.6 |

17.5 |

6.5 |

5/16-24UNF |

2550 |

1500 |

| NA207 |

35 |

|

72 |

20 |

51.1 |

37.6 |

18.8 |

55.6 |

17.5 |

6.5 |

M8x1 |

2550 |

1500 |

| NA207-23 |

36.513 |

1

7/16 |

72 |

20 |

51.1 |

37.6 |

18.8 |

55.6 |

17.5 |

6.5 |

5/16-24UNF |

2550 |

1500 |

| NA208-24 |

38.1 |

11/2 |

80 |

21 |

56.3 |

42.8 |

21.4 |

60.3 |

18.3 |

6.5 |

5/16-24UNF |

2950 |

1800 |

| NA208-25 |

39.688 |

1

9/16 |

80 |

21 |

56.3 |

42.8 |

21.4 |

60.3 |

18.3 |

6.5 |

5/16-24UNF |

2950 |

1800 |

| NA208 |

40 |

|

80 |

21 |

56.3 |

42.8 |

21.4 |

60.3 |

18.3 |

6.5 |

M8x1 |

2950 |

1800 |

| NA209-26 |

41.275 |

15/8 |

85 |

22 |

56.3 |

42.8 |

21.4 |

63.5 |

18.3 |

6.5 |

5/16-24UNF |

3180 |

2050 |

| NA209-27 |

42.863 |

1

11/16 |

85 |

22 |

56.3 |

42.8 |

21.4 |

63.5 |

18.3 |

6.5 |

5/16-24UNF |

3180 |

2050 |

| NA209-28 |

44.45 |

13/4 |

85 |

22 |

56.3 |

42.8 |

21.4 |

63.5 |

18.3 |

6.5 |

5/16-24UNF |

3180 |

2050 |

| NA209 |

45 |

|

85 |

22 |

56.3 |

42.8 |

21.4 |

63.5 |

18.3 |

6.5 |

M8x1 |

3180 |

2050 |

| NA210-31 |

49.213 |

1

15/16 |

90 |

24 |

62.7 |

49.2 |

24.6 |

69.9 |

18.3 |

6.5 |

5/16-24UNF |

3500 |

2300 |

| NA210 |

50 |

|

90 |

24 |

62.7 |

49.2 |

24.6 |

69.9 |

18.3 |

6.5 |

M8x1 |

3500 |

2300 |

| NA210-32 |

50.8 |

2 |

90 |

24 |

62.7 |

49.2 |

24.6 |

69.9 |

18.3 |

6.5 |

5/16-24UNF |

3500 |

2300 |

| NA211-32 |

50.8 |

2 |

100 |

25 |

71.4 |

55.6 |

27.8 |

76.2 |

20.7 |

8 |

3/8-24UNF |

4350 |

2900 |

| NA211 |

55 |

|

100 |

25 |

71.4 |

55.6 |

27.8 |

76.2 |

20.7 |

8 |

M10x1.25 |

4350 |

2900 |

| NA211-35 |

55.563 |

2

3/16 |

100 |

25 |

71.4 |

55.6 |

27.8 |

76.2 |

20.7 |

8 |

3/8-

24UNF |

4350 |

2900 |

| NA212-36 |

57.15 |

21/4 |

110 |

27 |

77.8 |

62 |

31 |

84.2 |

22.3 |

8 |

3/8-

24UNF |

4750 |

3250 |

| NA212 |

60 |

|

110 |

27 |

77.8 |

62 |

31 |

84.2 |

22.3 |

8 |

M10x1.25 |

4750 |

3250 |

| NA212-39 |

61.913 |

2

7/16 |

110 |

27 |

77.8 |

62 |

31 |

84.2 |

22.3 |

8 |

3/8-24UNF |

4750 |

3250 |

| NA213-40 |

63.5 |

21/2 |

120 |

28 |

85.7 |

68.6 |

34.1 |

86 |

23.5 |

8.5 |

3/8-24UNF |

5700 |

4000 |

| NA213 |

65 |

|

120 |

28 |

85.7 |

68.6 |

34.1 |

86 |

23.5 |

8.5 |

M10x1.25 |

5700 |

4000 |

| NA215-47 |

74.613 |

2

15/16 |

130 |

30 |

92.1 |

75 |

37.3 |

102 |

23.5 |

8.5 |

3/8-24UNF |

6600 |

4950 |

| NA215 |

75 |

|

130 |

30 |

92.1 |

75 |

37.3 |

102 |

23.5 |

8.5 |

M10x1.25 |

6600 |

4950 |

| NA215-48 |

76.2 |

3 |

130 |

30 |

92.1 |

75 |

37.3 |

102| |

23.5 |

8.5 |

3/8-24UNF |

6600 |

4950 |

1. ¿Qué tipos de rodamientos ofrecen??

Proporcionamos una amplia gama de rodamientos, que incluyen rodamientos de bolas, rodamientos de rodillos, rodamientos de bolas de surco profundo, rodamientos de contacto angular, rodamientos de rodillos cilíndricos, rodamientos autoalineables, rodamientos de empuje, rodamientos de agujas, y más. También nos especializamos en rodamientos cerámicos, híbridos, y rodamientos diseñados a medida.

2. ¿Ofrecen soluciones de rodamientos personalizadas??

Sí, proporcionamos servicios de producción de rodamientos OEM y personalizados adaptados a sus necesidades específicas. Comparta sus requisitos con nosotros, y nuestro equipo de expertos le ayudará a diseñar y fabricar la solución de rodamiento perfecta.

3. ¿Qué materiales se utilizan en sus rodamientos??

Nuestros rodamientos se fabrican con materiales de alta calidad como Gcr15, acero inoxidable (304, 316, 440C), nitruro de silicio (Si3N4), zirconia (ZrO₂), PEEK, PTFE, y otros materiales avanzados para garantizar durabilidad, precisión, y fiabilidad en diversas aplicaciones.

4. ¿Puede proporcionar muestras antes de realizar un pedido al por mayor??

Sí, ofrecemos rodamientos de muestra para pruebas y evaluación. Por favor, contáctenos con su solicitud de muestra, y estaremos encantados de ayudarle.

5. ¿Qué industrias atienden??

Atendemos a una amplia gama de industrias, incluyendo automotriz, aeroespacial, agricultura, maquinaria, procesamiento de alimentos, equipos médicos, automatización industrial, y energía renovable.

6. ¿Exportan sus productos??

Sí, exportamos rodamientos a nivel mundial, incluyendo a Europa, América del Norte, Asia, y otras regiones. Nuestros productos cumplen con los estándares internacionales de calidad y han sido bien recibidos por los clientes en todo el mundo.

7. ¿Cuál es su cantidad mínima de pedido? (MOQ)?

Nuestra MOQ varía dependiendo del tipo de producto y los requisitos de personalización. Para productos estándar, ofrecemos opciones de MOQ flexibles. Contáctenos para obtener detalles específicos de sus necesidades.

8. ¿Cuál es su tiempo de entrega de producción??

Los tiempos de entrega dependen del tipo de rodamiento y la cantidad de pedido. Los rodamientos estándar generalmente están listos para el envío dentro de 2-4 semanas, mientras que los pedidos personalizados pueden tardar más. Nos esforzamos por entregar pedidos puntualmente para cumplir con sus plazos.

9. ¿Cómo aseguran la calidad del producto??

Nuestros rodamientos se fabrican bajo estrictas medidas de control de calidad, incluyendo certificaciones ISO, pruebas de precisión, y rigurosas inspecciones. Cada producto es probado para garantizar el cumplimiento de los estándares internacionales.

10. ¿Qué métodos de pago aceptan??

Aceptamos múltiples métodos de pago, incluyendo transferencia bancaria (T/T), PayPal, y tarjetas de crédito. Contacte a nuestro equipo de ventas para más asistencia respecto a las opciones de pago.

11. ¿Proporcionan soporte técnico??

Sí, nuestro equipo experimentado ofrece soporte técnico y orientación para ayudarle a elegir el rodamiento adecuado para su aplicación. También estamos disponibles para consultas sobre servicio postventa y mantenimiento.

12. ¿Cómo puedo hacer un pedido??

Puede hacer un pedido contactándonos a través de nuestro sitio web, correo electrónico, o teléfono. Nuestro equipo de ventas le guiará a través del proceso y garantizará una transacción sin problemas.

13. ¿Puedo rastrear mi envío??

Sí, una vez que su pedido sea enviado, Proporcionaremos un número de seguimiento y detalles para ayudarle a monitorear su envío hasta que llegue a su destino.

14. ¿Cuál es su política de devoluciones??

Aceptamos devoluciones de rodamientos defectuosos o dañados dentro de un plazo específico. Por favor, revise nuestra política de devoluciones o contacte a nuestro equipo de servicio al cliente para obtener asistencia.

15. ¿Cómo puedo contactarlos para más información??

Puede comunicarse con nosotros por correo electrónico, teléfono, o a través del formulario de contacto en nuestro sitio web. Visite nuestra Contáctenos página para información detallada.

1. Amplia experiencia

Con más de una década de experiencia en la industria de rodamientos, nos hemos establecido como un proveedor confiable que ofrece productos de alta calidad a clientes en todo el mundo.

2. Calidad Premium

Nuestros rodamientos se fabrican utilizando materiales de primera calidad y tecnología de vanguardia, asegurando durabilidad, precisión, y cumplimiento con estándares internacionales como ISO y ANSI.

3. Amplia gama de productos

Ofrecemos una selección completa de rodamientos, que incluyen rodamientos de bolas, rodamientos de rodillos, rodamientos de cerámica, rodamientos híbridos, y soluciones diseñadas a medida para satisfacer las diversas necesidades de nuestros clientes.

4. Personalización y servicios OEM

Nos especializamos en la fabricación personalizada y servicios OEM adaptados a sus requisitos únicos. Comparta sus especificaciones, y crearemos la solución perfecta para su aplicación.

5. Precios competitivos

Como fabricante directo, ofrecemos precios competitivos sin comprometer la calidad, asegurando un valor excepcional para nuestros clientes.

6. Alcance global

Nuestros rodamientos son confiables para clientes en Europa, América del Norte, Asia, y más allá. Contamos con una red de logística global bien establecida para entregar productos de manera eficiente y a tiempo.

7. Pericia técnica y soporte

Nuestro equipo profesional brinda orientación técnica para ayudarlo a seleccionar el rodamiento adecuado para su aplicación. También ofrecemos excelentes soporte posventa para mantenimiento y resolución de problemas.

8. Estricto control de calidad

Cada rodamiento se somete a rigurosas pruebas e inspecciones para garantizar un rendimiento y una fiabilidad óptimos en entornos exigentes.

9. Fabricación respetuosa con el medio ambiente

Estamos comprometidos con la sostenibilidad, Uso de procesos y materiales ecológicos para reducir nuestro impacto medioambiental manteniendo la excelencia del producto.

10. Enfoque centrado en el cliente

Su satisfacción es nuestra máxima prioridad. Construimos asociaciones duraderas con nuestros clientes al proporcionar un servicio excepcional, respuestas rápidas, y soluciones a medida.