CS-Serie Radial-Rillenkugellager sind eine vielseitige und langlebige Lösung, die für radiale Lastanwendungen entwickelt wurde. Diese Lager verfügen über ein Einsatzlager, das in einem robusten Gehäuse montiert ist, bietet einfache Montage und hervorragende Leistung in verschiedenen Industriezweigen. Bekannt für ihre Anpassungsfähigkeit, CS-Serienlager sind für Schwerlast- und hochpräzise Anwendungen geeignet.

Funktionen

- Integriertes Design: Lagergehäuse- und Einsatzlagerbaugruppe vereinfacht Installation und Wartung.

- Korrosionsbeständigkeit: Erhältlich in Edelstahl für höhere Rost- und Korrosionsbeständigkeit.

- Sichere Passung: Ausgestattet mit exzentrischen Klemmringen oder Stellschrauben zur Gewährleistung der Stabilität unter Last.

- Dichtungsoptionen: Kommt mit effizienten Dichtungsoptionen zum Schutz vor Staub und Verunreinigungen.

- Vielseitige Montage: Geeignet für verschiedene Gehäuse, einschließlich Gleitlager- und Flanschgehäusen.

- Hohe Tragfähigkeit: Konstruiert, um sowohl radiale als auch moderate axiale Lasten effektiv zu tragen.

Anträge

- Landwirtschaftliche Maschinen

- Förderanlagen

- Materialhandhabungsgeräte

- Lebensmittel- und Getränkeverarbeitung

- Verpackungsmaschinen

- HLK-Systeme

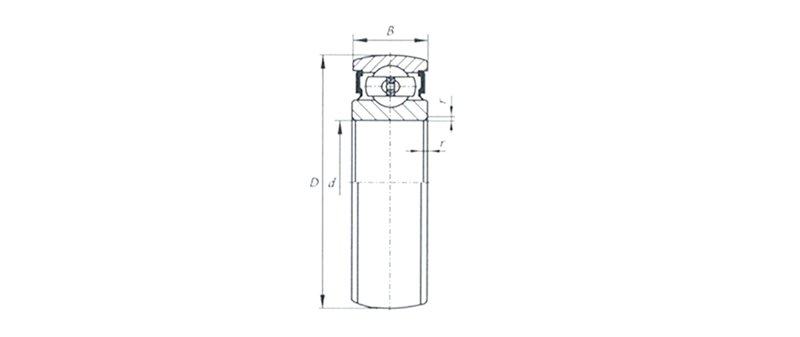

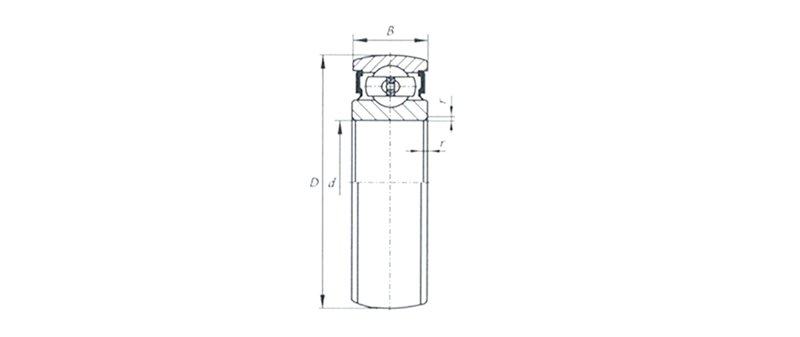

| Lagerbezeichnung |

Dimension(Mm) |

Basislastwerte (kN) |

| d |

D |

C |

B |

r min |

Cr |

Kor |

| CS201 |

12 |

32 |

10 |

10 |

0.6 |

680 |

300 |

| CS202 |

15 |

35 |

11 |

11 |

0.6 |

760 |

370 |

| CS203 |

17 |

40 |

12 |

12 |

0.6 |

960 |

480 |

| CS204 |

20 |

47 |

14 |

14 |

1 |

1280 |

660 |

| CS205 |

25 |

52 |

15 |

15 |

1 |

1400 |

790 |

| CS305 |

25 |

62 |

17 |

17 |

1.1 |

2250 |

1150 |

| CS206 |

30 |

62 |

16 |

16 |

1 |

1950 |

1150 |

| CS306 |

30 |

72 |

19 |

19 |

1.1 |

2700 |

1500 |

| CS207 |

35 |

72 |

17 |

17 |

1.1 |

2550 |

1500 |

| CS307 |

35 |

80 |

21 |

21 |

1.5 |

3350 |

1920 |

| CS208 |

40 |

80 |

18 |

18 |

1.1 |

2950 |

1800 |

| CS308 |

40 |

90 |

23 |

23 |

1.5 |

4080 |

2400 |

| CS209 |

45 |

85 |

19 |

19 |

1.1 |

3150 |

2080 |

| CS309 |

45 |

100 |

25 |

25 |

1.5 |

5280 |

3150 |

| CS210 |

50 |

90 |

20 |

20 |

1.1 |

3500 |

2320 |

| CS310 |

50 |

110 |

27 |

27 |

2 |

6180 |

3800 |

1. Welche Arten von Lagern bieten Sie an??

Wir bieten eine breite Palette von Lagern an, inklusive Kugellager, Wälzlager, Rillenkugellager, Schrägkugellager, Zylinderrollenlager, selbstausrichtende Lager, Axiallager, Nadellager, und mehr. Wir sind auch auf Keramik spezialisiert, hybrid, und kundenspezifische Lager.

2. Bieten Sie kundenspezifische Lagerlösungen an??

Ja, Wir bieten OEM- und kundenspezifische Lagerproduktionsdienstleistungen an, die auf Ihre spezifischen Bedürfnisse zugeschnitten sind. Teilen Sie uns Ihre Anforderungen mit, und unser Expertenteam hilft Ihnen bei der Entwicklung und Herstellung der perfekten Lagerlösung.

3. Welche Materialien werden in Ihren Lagern verwendet??

Unsere Lager werden aus hochwertigen Materialien wie z.B. Gcr15 gefertigt, Edelstahl (304, 316, 440C), Siliciumnitrid (Si3N4), Zirkonia (ZrO₂), SPÄHEN, PTFE, und andere fortschrittliche Materialien, um die Haltbarkeit zu gewährleisten, Präzision, und Zuverlässigkeit in verschiedenen Anwendungen.

4. Können Sie Muster zur Verfügung stellen, bevor Sie eine Großbestellung aufgeben??

Ja, Wir bieten Musterlager zur Prüfung und Bewertung an. Bitte kontaktieren Sie uns mit Ihrer Musteranfrage, und wir helfen Ihnen gerne weiter.

5. Welche Branchen bedienen Sie??

Wir bedienen eine Vielzahl von Branchen, einschließlich Automotive, Luft- und Raumfahrt, Landwirtschaft, Maschinerie, Lebensmittelverarbeitung, Medizinische Geräte, Industrielle Automatisierung, und erneuerbare Energien.

6. Exportieren Sie Ihre Produkte??

Ja, Wir exportieren Lager weltweit, auch nach Europa, Nordamerika, Asien, und andere Regionen. Unsere Produkte entsprechen internationalen Qualitätsstandards und werden von Kunden weltweit gut angenommen.

7. Was ist Ihre Mindestbestellmenge? (Mindestbestellmenge)?

Unser MOQ variiert je nach Produkttyp und Anpassungsanforderungen. Für Standardprodukte, Wir bieten flexible MOQ-Optionen. Kontaktieren Sie uns für Details, die auf Ihre Bedürfnisse zugeschnitten sind.

8. Was ist Ihre Produktionsvorlaufzeit??

Die Lieferzeiten sind abhängig von der Art des Lagers und der Bestellmenge. Standardlager sind in der Regel innerhalb von 2-4 Wochen, Während kundenspezifische Bestellungen länger dauern können. Wir bemühen uns, Bestellungen pünktlich zu liefern, um Ihre Fristen einzuhalten.

9. Wie stellen Sie die Produktqualität sicher??

Unsere Lager werden unter strengen Qualitätskontrollmaßnahmen hergestellt, einschließlich ISO-Zertifizierungen, Präzisionsprüfung, und strenge Inspektionen. Jedes Produkt wird getestet, um die Einhaltung internationaler Standards sicherzustellen.

10. Welche Zahlungsmethoden akzeptieren Sie??

Wir akzeptieren mehrere Zahlungsmethoden, inklusive Überweisung (T/T), PayPal, und Kreditkarten. Wenden Sie sich an unser Vertriebsteam, um weitere Unterstützung zu den Zahlungsoptionen zu erhalten.

11. Bieten Sie technischen Support an??

Ja, Unser erfahrenes Team bietet technischen Support und Beratung, um Ihnen bei der Auswahl des richtigen Lagers für Ihre Anwendung zu helfen. Wir stehen Ihnen auch für Kundendienst- und Wartungsanfragen zur Verfügung.

12. Wie kann ich eine Bestellung aufgeben??

Sie können eine Bestellung aufgeben, indem Sie uns über unsere Website kontaktieren, E-Mail, oder Telefon. Unser Vertriebsteam wird Sie durch den Prozess führen und eine reibungslose Abwicklung sicherstellen.

13. Kann ich meine Sendung verfolgen??

Ja, Sobald Ihre Bestellung versandt wurde, Wir stellen Ihnen eine Sendungsverfolgungsnummer und Details zur Verfügung, damit Sie Ihre Sendung überwachen können, bis sie an Ihrem Zielort ankommt.

14. Was ist Ihr Rückgaberecht??

Wir akzeptieren Rücksendungen für defekte oder beschädigte Lager innerhalb eines bestimmten Zeitraums. Bitte lesen Sie unsere Rückgabebedingungen oder wenden Sie sich an unser Kundendienstteam, um Unterstützung zu erhalten.

15. Wie kann ich Sie für weitere Informationen kontaktieren??

Sie erreichen uns per E-Mail, Telefon, oder über das Kontaktformular auf unserer Website. Besuchen Sie unsere Kontaktieren Sie uns Seite für detaillierte Informationen.

1. Umfangreiche Erfahrung

Mit über einem Jahrzehnt Erfahrung in der Wälzlagerindustrie, Wir haben uns als vertrauenswürdiger Lieferant etabliert, der Kunden weltweit qualitativ hochwertige Produkte liefert.

2. Premium-Qualität

Unsere Lager werden unter Verwendung hochwertiger Materialien und modernster Technologie hergestellt, Gewährleistung der Langlebigkeit, Präzision, und Einhaltung internationaler Standards wie ISO und ANSI.

3. Breites Produktsortiment

Wir bieten eine umfassende Auswahl an Lagern, inklusive Kugellager, Wälzlager, Keramik-Lager, Hybrid-Lager, und maßgeschneiderte Lösungen, um den vielfältigen Bedürfnissen unserer Kunden gerecht zu werden.

4. Anpassung und OEM-Dienstleistungen

Wir sind spezialisiert auf kundenspezifische Fertigung und OEM-Dienstleistungen, die auf Ihre individuellen Anforderungen zugeschnitten sind. Teilen Sie Ihre Spezifikationen mit, und wir erstellen die perfekte Lösung für Ihre Anwendung.

5. Wettbewerbsfähige Preisgestaltung

Als direkter Hersteller, Wir bieten wettbewerbsfähige Preise ohne Kompromisse bei der Qualität, Gewährleistung eines außergewöhnlichen Mehrwerts für unsere Kunden.

6. Globale Reichweite

Kunden in Europa vertrauen auf unsere Lager, Nordamerika, Asien, und darüber hinaus. Wir verfügen über ein gut etabliertes globales Logistiknetzwerk, um Produkte effizient und pünktlich zu liefern.

7. Technisches Know-how und Support

Unser professionelles Team bietet technische Beratung, um Sie bei der Auswahl des richtigen Lagers für Ihre Anwendung zu unterstützen. Wir bieten auch einen hervorragenden After-Sales-Support für Wartung und Fehlerbehebung.

8. Strenge Qualitätskontrolle

Jedes Lager wird strengen Tests und Inspektionen unterzogen, um eine optimale Leistung und Zuverlässigkeit in anspruchsvollen Umgebungen zu gewährleisten.

9. Umweltfreundliche Herstellung

Wir setzen uns für Nachhaltigkeit ein, Verwendung umweltfreundlicher Prozesse und Materialien, um unsere Umweltbelastung zu reduzieren und gleichzeitig die Exzellenz der Produkte zu erhalten.

10. Kundenorientierter Ansatz

Ihre Zufriedenheit steht für uns an erster Stelle. Wir bauen dauerhafte Partnerschaften mit unseren Kunden auf, indem wir außergewöhnlichen Service bieten, Schnelle Antworten, und maßgeschneiderte Lösungen.