Funktionen und Anwendungen von 6000 Serie Rillenkugellager

Funktionen:

- Breite Kompatibilität:

Konzipiert für eine breite Palette von Anwendungen, Wirtschaftlichkeit und Leistung in Einklang bringen. - Vielseitiges Lastmanagement:

Unterstützt sowohl radiale als auch begrenzte axiale Lasten, Dadurch wird es an unterschiedliche mechanische Umgebungen angepasst. - Langlebige Konstruktion:

Hergestellt aus hochwertigen Materialien wie Chromstahl oder Edelstahl für lang anhaltende Zuverlässigkeit. - Kompakt und leicht:

Das optimierte Design sorgt für eine effiziente Raumnutzung bei gleichzeitig hoher Festigkeit und Tragfähigkeit. - Geringe Reibung:

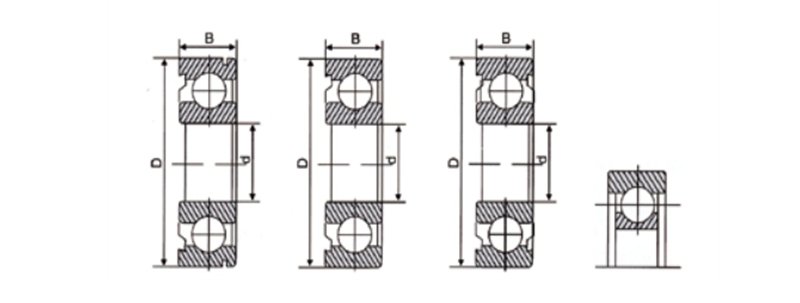

Glatte Wälzkörper reduzieren Reibung und Hitze, Steigerung der Effizienz und Lebensdauer. - Kundenspezifische Dichtungsoptionen:

Offen verfügbar, versiegelt (2RS), und geschirmt (ZZ) Konfigurationen, um spezifische Betriebsbedingungen zu erfüllen. - Leistung bei hoher Geschwindigkeit:

Geeignet für hohe Drehzahlen, Geeignet für Präzisionsgeräte und Industriemaschinen. - Korrosionsbeständigkeit (Wahlfrei):

Edelstahlvarianten bieten hervorragenden Schutz in korrosiven Umgebungen.

Anträge:

- Automobil-Komponenten:

Weit verbreitet in Lichtmaschinen, Vorspeisen, und Klimaanlagen. - Industriemaschinen:

Unverzichtbar für Pumpen, Förderer, Fans, und Getriebe in Fertigungsanlagen. - Haushaltsgeräte:

Häufig in Waschmaschinen zu finden, Trockner, und andere motorisierte Geräte. - Elektrowerkzeuge:

Gewährleistet eine hohe Geschwindigkeit und einen reibungslosen Betrieb in Bohrmaschinen, schleifmaschinen, und Sägen. - Sportausrüstung:

Wird in Fahrrädern verwendet, Skateboards, und Fitnessgeräte durch kompakte Größe und Langlebigkeit. - Medizinprodukte:

Geeignet für Diagnosemaschinen und andere Präzisionsinstrumente, die Zuverlässigkeit und Geräuscharmut erfordern. - Luft- und Raumfahrt und Schifffahrt:

Kompakte und korrosionsbeständige Varianten erfüllen die hohen Anforderungen in diesen Branchen.

| Lagerbezeichnung | Dimension(Mm) | Grundlast einschaltquoten (Kn) |

Geschwindigkeit einschaltquoten(Rpm) |

Gewicht | |||||||

| Offen | RS | ZZ | d | D | B | RS Min |

Cr | Kor | Fett | Öl | (Kg) |

| 6000 | 6000 RS |

6000 ZZ |

10 | 26 | 8 | 0.3 | 4.55 | 1.96 | 2900 | 3400 | 0.019 |

| 6001 | 6001 RS |

6001 ZZ |

12 | 28 | 8 | 0.3 | 5.1 | 2.39 | 2600 | 3000 | 0.021 |

| 6002 | 6002 RS |

6002 ZZ |

15 | 32 | 9 | 0.3 | 5.6 | 2.83 | 2200 | 2600 | 0.03 |

| 6003 | 6003 RS |

6003 ZZ |

17 | 35 | 10 | 0.3 | 6.8 | 3.35 | 2000 | 2400 | 0.039 |

| 6004 | 6004 RS |

6004 ZZ |

20 | 42 | 12 | 0.6 | 9.4 | 5.05 | 1800 | 2100 | 0.069 |

| 6005 | 6005 RS |

6005 ZZ |

25 | 47 | 12 | 0.6 | 10.1 | 5.85 | 1500 | 1800 | 0.08 |

| 6006 | 6006 RS |

6006 ZZ |

30 | 55 | 13 | 1 | 13.2 | 8.3 | 1300 | 1500 | 0.116 |

| 6007 | 6007 RS |

6007 ZZ |

35 | 62 | 14 | 1 | 16 | 10.3 | 1200 | 1400 | 0.155 |

| 6008 | 6008 RS |

6008 ZZ |

40 | 68 | 15 | 1 | 16.8 | 11.5 | 1000 | 1200 | 0.19 |

| 6009 | 6009 RS |

6009 ZZ |

45 | 75 | 16 | 1 | 21 | 15.1 | 9200 | 1100 | 0.237 |

| 6010 | 6010 RS |

6010 ZZ |

50 | 80 | 16 | 1 | 21.8 | 16.6 | 8400 | 9000 | 0.261 |

| 6011 | 6011 RS |

6011 ZZ |

55 | 90 | 18 | 1.1 | 28.3 | 21.2 | 7700 | 9000 | 0.388 |

| 6012 | 6012 RS |

6012 ZZ |

60 | 95 | 18 | 1.1 | 29.5 | 23.2 | 7300 | 8300 | 0.414 |

| 6013 | 6013 RS |

6013 ZZ |

65 | 100 | 18 | 1.1 | 30.5 | 25.2 | 6500 | 7700 | 0.421 |

| 6014 | 6014 RS |

6014 ZZ |

70 | 110 | 20 | 1.1 | 38 | 31 | 6100 | 7100 | 0.604 |

| 6015 | 6015 RS |

6015 ZZ |

75 | 115 | 20 | 1.1 | 39.5 | 33.5 | 5700 | 6700 | 0.649 |

| 6016 | 6016 RS |

6016 ZZ |

80 | 125 | 22 | 1.1 | 47.5 | 40 | 5300 | 6200 | 0.854 |

| 6017 | 6017 RS |

6017 ZZ |

85 | 130 | 22 | 1.1 | 49.5 | 43 | 5000 | 5900 | 0.89 |

| 6018 | 6018 RS |

6018 ZZ |

90 | 140 | 24 | 1.5 | 58 | 49.5 | 4700 | 5600 | 1.02 |

| 6019 | 6019 RS |

6019 ZZ |

95 | 145 | 24 | 1.5 | 60.5 | 54 | 4500 | 5300 | 1.08 |

| Offen | RS | ZZ | d | D | B |

RS Min |

Cr | Kor | Fett | Öl | (Kg) |

| 6020 | 6020 RS |

6020 ZZ |

100 | 150 | 24 | 1.5 | 60 | 54 | 4200 | 5000 | 1.15 |

| 6021 | 6021 RS |

6021 ZZ |

105 | 160 | 26 | 2 | 72.5 | 65.5 | 4000 | 4700 | 1.59 |

| 6022 | 6022 RS |

6022 ZZ |

110 | 170 | 28 | 2 | 82 | 73 | 3800 | 4500 | 1.96 |

| 6024 | 6024 RS |

6024 ZZ |

120 | 180 | 28 | 2 | 85 | 79.5 | 3500 | 4100 | 2.07 |

| 6026 | 6026 RS |

6026 ZZ |

130 | 200 | 33 | 2 | 106 | 101 | 3200 | 3800 | 3.16 |

| 6028 | 6028 RS |

6028 ZZ |

140 | 210 | 33 | 2 | 110 | 109 | 3000 | 3500 | 3.35 |

| 6030 | 6030 RS |

6030 ZZ |

150 | 225 | 35 | 2.1 | 126 | 126 | 2800 | 3200 | 4.08 |

| 6032 | 6032 RS |

6032 ZZ |

160 | 240 | 38 | 2.1 | 143 | 144 | 2600 | 3000 | 5.05 |

| 6034 | 6034 RS |

6034 ZZ |

170 | 260 | 42 | 2.1 | 168 | 172 | 2400 | 2800 | 6.76 |

| 6036 | 6036 RS |

6036 ZZ |

180 | 280 | 46 | 2.1 | 189 | 199 | 2300 | 2700 | 8.8 |

| 6038 | 6038 RS |

6038 ZZ |

190 | 290 | 46 | 2.1 | 197 | 215 | 2100 | 2500 | 9.18 |

| 6040 | 6040 RS |

6040 ZZ |

200 | 310 | 51 | 2.1 | 218 | 243 | 2000 | 2400 | 11.9 |

| 60/22 | 60/22 RS |

60/22 ZZ |

22 | 44 | 12 | 0.6 | 955 | 515 | 1700 | 2000 | 0.074 |

| 60/28 | 60/28 RS |

60/28 ZZ |

28 | 52 | 12 | 0.6 | 1270 | 755 | 1400 | 1600 | 0.098 |

| 60/32 | 60/32 RS |

60/32 ZZ |

32 | 58 | 13 | 1 | 1200 | 820 | 1200 | 1500 | 0.129 |